Corvus Gold Initial Gravity and Cyanide Leaching Tests Return High Recoveries Averaging 89% for Gold and 73% for Silver

Highlights: Coarse grind size of 65 mesh for gravity separation & 100 mesh for tail leaching tests

Vancouver, B.C… Corvus Gold Inc. (“Corvus” or the “Company”) – (TSX: KOR, OTCQX: CORVF) announces the results of the initial follow-up gravity gold recovery testing and cyanide leaching of the gravity tail material from the main vein and stockwork core of the Yellowjacket deposit. These test samples are representative of an estimated 70% of the gold and 85% of the silver within the Yellowjacket deposit estimated resource (follow-up to initial grind size test results announced in NR14-13, May 5, 2014).

These initial results have produced high weighted recoveries for this zone, with an average of 89.2% for gold and 73% for silver (Tables 1 and 2). Of interest, 40% of the gold (weighted average) recovers via gravity separation with the concentrate reporting to just 0.06% of the processed material (a very high concentration ratio of greater than 1500 to 1).

The residual tail material after the gravity separation process produced an average weighted recovery in cyanide bottle roll tests of approximately 84% for gold and 71% for silver, which is similar to the average gold recovery from the oxide heap leach material. In addition, reagent consumptions are low as in earlier studies, averaging below 0.15 kg/t CN and about 1.5 kg/t for lime. Test work is ongoing for the surrounding, primarily lower grade, material hosting the remaining estimated 30% of gold and 15% of silver within the Yellowjacket deposit.

The tests were conducted at a coarse grind size of 65 mesh for the gravity separation and 100 mesh for the bottle roll tests, confirming the earlier grind size optimization results reported in NR14-13. These results indicate a clear path to proceed with optimization studies for the design of a simple, coarse grind, high recovery, milling circuit for the Yellowjacket deposit.

The envisioned system would include initial gravity separation of coarse gold and silver followed by cyanide leaching of the gravity tail either as an agglomerated product on the leach pad or in a standard CIL leach circuit for final gold-silver recovery. The ongoing metallurgical testing will focus on maximizing gold-silver recovery and minimizing potential processing costs. These studies are intended to better define the mill flow sheet, plant design and estimated actual recovery predictions for operations.

Table 1 – Results of Gravity Recoverable Gold testing followed by Cyanide Bottle Roll testing of

the Yellowjacket Deposit Composites.

| Metallurgical Test Results | ||||||

| Metallurgical Composite | Calculated Au Head Grade (g/t) | Yellowjacket Mineralization Type* | % of Yellowjacket Deposit Contained Au | Gravity Gold Recovery (%) | Gravity Tail BRT, Additional Gold Recovery (%) | Total Gold Recovered in Tests (%) |

| YJPQ01 | 9.22 | Main Vein | 30% | 50.7 | 43.0 | 93.7 |

| YJPQ02 | 5.78 | Stockwork | 13% | 57.8 | 36.7 | 94.5 |

| YJPQ03 | 1.40 | Stockwork | 15% | 25.7 | 62.6 | 88.3 |

| YJPQ04 | 0.59 | Stockwork*** | 6% | 23.6 | 49.3 | 72.9 |

| YJPQ05 | 0.55 | Stockwork*** | 6% | ** | 76.4 | 76.4 |

*-consist of 17% Indicated and 83% Inferred Resource

**-no gravity recovery testing performed due to limited sample

***-mixed oxide and sulphide mineralization

Table 2 – Results of Gravity Recoverable Silver testing followed by Cyanide Bottle Roll testing

of the Yellowjacket Deposit Composites.

| Metallurgical Test Results | ||||||

| Metallurgical Composite | Calculated Ag Head Grade (g/t) | Yellowjacket Mineralization Type* | % of Yellowjacket Deposit Contained Ag | Gravity Silver Recovery (%) | Gravity Tail BRT Additional Silver Recovery (%) | Total Silver Recovered in Tests (%) |

| YJPQ01 | 47.4 | Main Vein | 45% | 11.7 | 63.4 | 75.1 |

| YJPQ02 | 20.0 | Stockwork | 11% | 5.8 | 71.2 | 76.9 |

| YJPQ03 | 8.2 | Stockwork | 15% | 2.3 | 68.9 | 71.2 |

| YJPQ04 | 4.9 | Stockwork*** | 7% | 1.9 | 62.3 | 64.2 |

| YJPQo5 | 0.6 | Stockwork*** | 7% | ** | 65.0 | 65.0 |

*-consist of 16% Indicated and 84% Inferred Resource

**-no gravity recovery testing performed due to limited sample

***-mixed oxide and sulphide mineralization

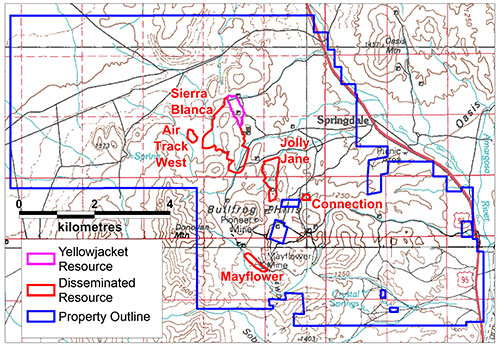

The Yellowjacket Deposit (Figure 1) remains open along strike to the north and south, and down dip as reflected in hole NB-13-370, drilled to a down dip extent of 170 metres, which intersected one of the best vein intervals drilled to date on the North Bullfrog Project (4.9m @ 21.2 g/t gold & 117.0 g/t silver within an overall vein stockwork zone of 42m @ 4.9 g/t gold & 30 g/t silver (NR14-03, January 22, 2014)). The Company’s continuing 2014 drill program is targeting the expansion of the Yellowjacket deposit and has defined to date a new vein system to the west (NB-14-378 – 9.2m @ 17.9 g/t gold and 260 g/t silver (NR14-11, April 3, 2014)) and an extension of the system to the north (NB-14-391 17.5m @ 12.8 g/t gold and 62 g/t silver (NR14-14, May 22, 2014)). In addition, the 2014 program will test new, large, structural zone targets which have the potential to host other Yellowjacket type high-grade systems.

Figure 1: Corvus land position at North Bullfrog with estimated resource areas shown.

About the North Bullfrog Project, Nevada

Corvus controls 100% of its North Bullfrog Project, which covers approximately 68 km² in southern Nevada. The property package is made up of a number of private mineral leases of patented federal mining claims and 758 federal unpatented mining claims. The project has excellent infrastructure, being adjacent to a major highway and power corridor as well as a large water right.

Based upon a USD 1300 gold price and a silver to gold price ratio of 59:1, the North Bullfrog Project currently has estimated mineral resources defined in six deposits: the structurally controlled Yellowjacket milling deposit and the oxidized disseminated heap leach Sierra Blanca, Jolly Jane, Air Track West, Connection and Mayflower deposits. The Yellowjacket vein-style deposit has an Indicated Mineral Resource of 3.69 Mt at an average grade of 1.03 g/t gold and 5.52 g/t silver for 122,000 contained ounces of gold and 654,000 ounces of silver and an Inferred Mineral Resource of 18.40 Mt with an average grade of 0.94 g/t gold and 6.16 g/t silver for 555,000 contained ounces of gold and 3.64M ounces of silver, both at a 0.29 g/t gold cutoff.

The five oxidized disseminated heap leach deposits contain an Indicated Mineral Resource of 25.72 Mt at an average grade of 0.29 g/t gold for 240,000 contained ounces of gold and an Inferred Mineral Resource of 185.99 Mt at 0.19 g/t gold for 1,120,000 contained ounces of gold (both at a 0.13 g/t gold cut-off), with appreciable silver credits.

For full details with respect to the assumptions underlying the current resource estimate detailed herein, and listing of all of the metallurgical testing data please review the Company’s latest NI 43-101 technical report entitled “Technical Report – The North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” dated April 1, 2014 and available on SEDAR or at the Company’s website www.corvusgold.com.

Qualified Person and Quality Control/Quality Assurance

Jeffrey A. Pontius (CPG 11044), a qualified person as defined by National Instrument 43-101, has supervised the preparation of the scientific and technical information that form the basis for this news release and has approved the disclosure herein. Mr. Pontius is not independent of Corvus, as he is the CEO and holds common shares and incentive stock options.

Carl E. Brechtel, (Nevada PE 008744 and Registered Member 353000 of SME), a qualified person as defined by National Instrument 43-101, has supervised execution of the work outlined in this news release and has approved the disclosure herein. Mr. Brechtel is not independent of Corvus, as he is the COO and holds common shares and incentive stock options.

Mr. Herbert Osborne, a consulting process engineer for Interralogic, Inc., has acted as the Qualified Person, as defined by NI 43-101, for evaluation of the metallurgical testing data presented in this news release. He has over 50 years of experience in mineral process design and operations. He is a registered Member of the Society of Mining, Metallurgy and Exploration (SME Member No. 2430050 RM). Mr. Osborne is independent of the Company under NI 43-101.

The work program at North Bullfrog was designed and supervised by Russell Myers (CPG 11433), President of Corvus, and Mark Reischman, Corvus Nevada Exploration Manager, who are responsible for all aspects of the work, including the quality control/quality assurance program. On-site personnel at the project log and track all samples prior to sealing and shipping. Quality control is monitored by the insertion of blind certified standard reference materials and blanks into each sample shipment. All resource sample shipments are sealed and shipped to ALS Chemex in Reno, Nevada, for preparation and then on to ALS Chemex in Reno, Nevada, or Vancouver, B.C., for assaying. ALS Chemex’s quality system complies with the requirements for the International Standards ISO 9001:2000 and ISO 17025:1999. Analytical accuracy and precision are monitored by the analysis of reagent blanks, reference material and replicate samples. Finally, representative blind duplicate samples are forwarded to ALS Chemex and an ISO compliant third party laboratory for additional quality control.

About Corvus Gold Inc.

Corvus Gold Inc. is a North American gold exploration company, which is focused on advancing its 100% controlled Nevada, North Bullfrog project towards a potential development decision. In addition, the Company controls a number of other North American exploration properties representing a spectrum of gold, silver and copper projects.

On behalf of

Corvus Gold Inc.

(signed) Jeffrey A. Pontius

Jeffrey A. Pontius,

Chief Executive Officer

Contact Information:

Ryan Ko

Investor Relations

Email: info@corvusgold.com

Phone: 1-888-770-7488 (toll free) or (604) 638-3246 /Fax: (604) 408-7499

Cautionary Note Regarding Forward-Looking Statements